Here are a few of the research projects using the TEM:

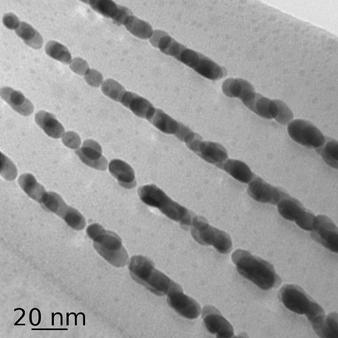

The Malac and Meldrum groups are developing electron beam tomography methods using the field emission TEM laboratory at the NINT. Nanocrystal tomography is especially challenging, however, because the samples do not have features that can be tracked easily as the sample is rotated. Here, we see an image of a test sample for tomographic reconstruction. It consists of a 4-period layer of gold nanoparticles separated by SiO2 buffers. Because the Au particles are fairly large and separated vertically in a controlled manner, it should be easier to track individual particles for tomographic reconstruction. Ultimately, we hope to develop true 3D nanoparticle maps using these new techniques.

Integrated air-core waveguides are attracting interest for lab-on-chip and optical interconnect applications. Amongst other attributes, they have potential for widely tunable operation using MEMS-based actuation techniques. Strategies for the fabrication of hollow waveguides include sacrificial etching, wafer bonding, and chemical vapor deposition in a pre-defined trench. An alternative developed in the DeCorby group is based on the controlled formation of straight-sided delamination buckles within a multilayer thin film stack. This TEM image shows the DBR-type 4-period Si-SiO2 mirrors used to form the reflective layers. Patterned buckling of these layers produces the omnidirection mirrors with operation wavelengths down to ~800 nm.

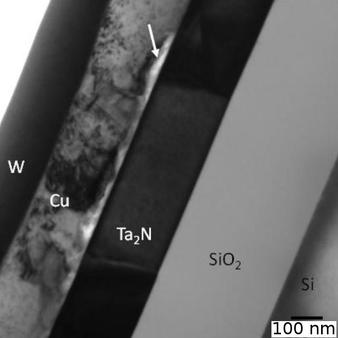

This figure shows the bright field image of the cross section of a Cu metallization stack on Si/SiO2 substrate with 200 nm Ta2N as diffusion barrier, from the Doug Ivey research group. The TEM cross section is prepared utilizing focused ion beam (FIB) which requires deposition of a conductive coating (W in this case) on the surface. The arrow marks the region within Cu layer where voids form as a result of diffusion of Cu into Ta2N. TEM observation provides an accurate method to determine the failure temperature of these metallization stacks

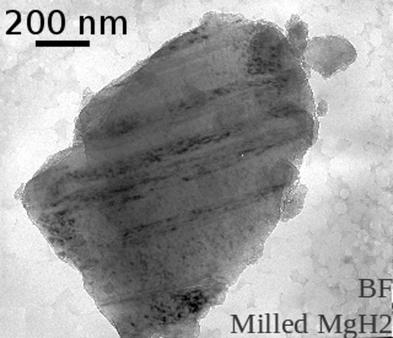

Magnesium hydride (MgH2) is by far the most extensively studied metal hydride for hydrogen storage applications. The widespread utilization of this hydride is mainly hindered by its sluggish kinetics in releasing hydrogen during desorption. High-energy ball milling of MgH2 powder can significantly enhance this kinetics. Little was known about the defects and microstructure of the ball-milled MgH2 powder due to extreme instability of this phase at ambient temperature in TEM. Micrographs here were acquired using a cryogenic TEM holder (T = 90K), extending the stability time of the hydride phase under the electron beam (Dave Mitlin group). This enabled us to perform a detailed defect analysis on the milled microstructure. Milling causes extensive twinning in the hydride phase, which may contribute to the hydrogen desorption kinetics.